Last week, I looked at the wide range of technologies available for electricity storage to support renewable energy grids.

Gravity systems are the dominant form of electricity storage today. Current installations can store up to 9,000 GWh—about a quarter of the world’s average daily electricity consumption.

Using gravity to store electricity relies on some very simple physics. You must put in work to lift a mass (m) against the earth’s gravity (g) to a height (m). When the mass falls, the work converts back into energy. The energy stored is:

E = m x g x h

The earth’s gravity, for our purposes, provides a constant acceleration of 9.8 metres per second per second. So if we lift 1 kg by 1 m, we have stored 9.8 joules (J). That’s not much energy. It will only raise the temperature of a litre of water by 0.002 °C. Hard to boil a kettle that way. But when we start talking about thousands of tonnes and hundreds of metres, we can power homes, transport and industry.

So, storing energy through gravity is simple. Think of it like winding up the weights on a grandfather clock. You put the effort in to raise the weights, and as they descend, they power the clock.

There are several ways to exploit gravity storage.

Pumped hydro storage

We are all familiar with hydroelectricity. To generate electricity, dam a river and let water out through a turbine. The first recorded application of hydroelectric generation was in 1878 at the engineer William Armstrong’s home at Cragside in Northumberland. In 1882, the first commercial system opened on the Fox River in Wisconsin. Since then, it has grown to supply 17% of the world’s electricity.

It wasn’t long before someone thought that pumping water uphill when you have an excess of electricity would fill a reservoir you could tap when you needed the electricity again. The first pumped hydro storage facility was built in Switzerland in 1907, followed by the first US station in 1930. My local station at Dinorwig in North Wales started up in 1984.

The upper reservoir at Dinorwig pumped-hydro storage facility

Dinorwig is a typical pumped hydro storage facility. They built the upper reservoir in an abandoned slate quarry high up in the mountains of Snowdonia, 100 m above the lower reservoir. Dinorwig has a capacity of 9.1 GWh, a maximum output of 1.8 GW, and can go from a standstill to full output in about 75 seconds. A full reservoir can deliver full power for six hours, consuming 390 m3 of water each second.

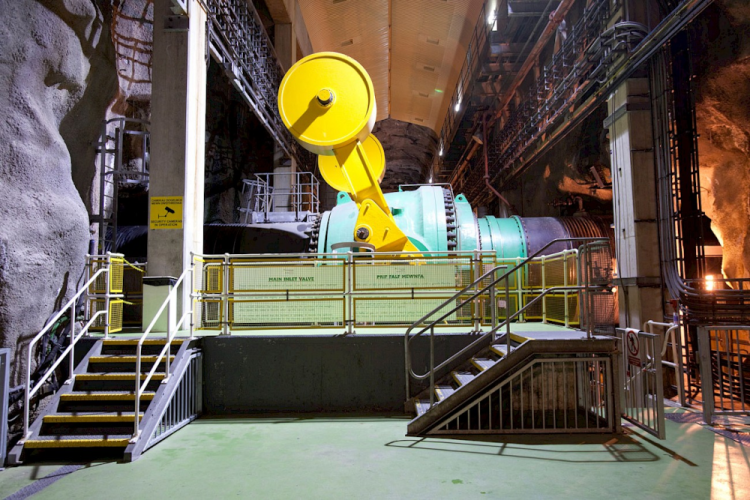

Inlet valves at Dinorwig

It is an engineering marvel and a popular tourist attraction; with the biggest pipes and valves I have seen anywhere.

Pumped hydro accounts for around 95% of all the installed electricity storage capacity in the world. It is simple, relies on established technologies, and is easily scalable. Efficiency in storage systems is essential. How much electricity do I get back for each unit I put in? Allowing for pump and turbine performance, evaporation, and other losses, pumped hydro’s ‘round-trip’ efficiency is around 70% – 80%.

So, it is all good and pumped hydro has a deserved dominant position in global electricity storage. However, it isn’t perfect. You need big hills or mountains, and a good supply of water. Pumped hydro involves major civil engineering works, so the capital costs are high, and only large systems make economic sense. Dinorwig involved removing twelve million tonnes of rock from the mountain, creating 16 km of tunnels and a 4000 m2 artificial cavern 51m high.

The second problem with pumped hydro is that it cannot meet all the support requirements of an electricity grid with lots of renewables. It is great for load balancing, shifting power from quiet periods (at night) to the evening peak. It can also provide fast emergency backup if a generator falls off the grid. But it is not fast enough to buffer the rapid fluctuations that can occur.

An AC electricity grid must keep voltage and frequency within tight limits to avoid problems with attached equipment. In the old days, we generated electricity with massive steam turbines and generators—big pieces of rotating metal providing mechanical inertia to resist fluctuations. Renewables don’t offer the same inertia, so we need another way to stabilise the grid. That means storage again, but fast acting. Much faster than pumped hydro.

How are people building on pumped hydro experience to provide more flexibility?

Pumped hydro with heavy liquids

A limitation of pumped hydro is that water is not very dense. To store a useful amount of energy, you must pump a lot of water to a significant height. So, large systems with lots of civil engineering in the right geography. However, liquids are convenient because they can be poured into any shape. Could we use a liquid that is denser than water?

The startup RheEnergise is taking exactly that approach. They plan to replace water in open reservoirs with a closed-loop system using a proprietary working fluid that is 2.5 times as dense as water. That means you need a smaller volume and/or a smaller vertical distance, saving costs and opening up more locations. Since construction accounts for 65% of pumped energy storage costs, a smaller system is simpler and cheaper to install.

RheEnergise target smaller systems with outputs of 10 MW to 50 MW, using hills rather than mountains. They estimate there are 9,500 suitable sites in the UK, 80,000 in Europe, and 160,000 in Africa. RheEnergise has no commercial projects but has support from the UK and Canadian governments for demonstration projects. They plan the first for Cumbernauld in Scotland.

Let’s pump some iron!

Pumped hydro energy storage systems lift water through a gravitational gradient to store energy. Another approach is to raise and lower heavy weights—a larger-scale version of the grandfather clock. Lift the weights against gravity when excess renewable energy is available using electric winches. Allow the weights to fall back down to drive the winches as generators. Concrete is 2.5 times as dense as water and iron 8 times, making storage more compact.

Although they are at the research or early prototype/demonstration stage, three companies are exploring this concept.

Advanced Rail Energy Systems (ARES) use heavy rail cars on an inclined plane. An electrically powered chain pulls the cars up the incline, recovering the energy as they return to the bottom. ARES are developing a 50 MW facility on a 20-acre site in a Nevada gravel mine. The project has 210 cars, weighing a total of 75,000 tonnes on 10 parallel rail tracks. With a 3-second response time, this system will help regulate the local California grid. ARES believe they can scale the system to provide power outputs from 5 MW to 1 GW with a storage duration of 15 mins to over 24 hours and a round-trip efficiency greater than 90%.

The key challenge with ARES is space. It is best suited to areas with lots of elbow room and gentle slopes.

Gravitricity energy storage system

Gravitricity takes an alternative approach. They lift a weight vertically up and down a shaft, either a disused mine shaft or a purpose-bored shaft. Their design gives a very fast response time with zero to full power in less than one second and a round-trip efficiency between 80% and 90%. The weights range from 500 to 5000 tons, and shafts can be 150 m to 1500 m deep. This gives a range of output powers from 1 MW to 20 MW with a duration of 15 mins to 8 hours.

After successful trials of an above-ground prototype, Gravitricity has received funding to build a full-scale system in Yorkshire. The project will dig a new shaft 10 m in diameter and 250 m deep and will be able to store 4 MWh.

The challenge for Gravitricity is finding or digging the shafts. It is well-established technology but needs a suitable geology.

Energy Vault demonstration facility in Switzerland

Energy Vault uses a similar approach to Gravitricity but puts the entire system above ground. Automated cranes use surplus electricity to build a tower out of heavy concrete blocks. The weights are lowered back to the ground to recover the energy. A single tower could provide 35 MWh of storage, delivering 4 to 8 MW of continuous power for 8 to 16 hours.

Energy Vault is currently preparing to install a 2 GWh system in China.

Energy Vault has the advantage of being above ground compared to Gravitricity but is exposed to the weather. Automatically finding, locking on to, and delivering heavy concrete blocks to a precise location is not a trivial task. Bad weather, especially high winds, can make the job difficult. Will the Energy Vault systems operate successfully 24/7 in all weathers? It is a real engineering challenge!

Summary

- Using gravity to store electricity accounts for 95% of the world’s storage capacity

- Pumped hydro storage is the dominant form of gravity storage, providing 9 GWh of installed capacity

- New solutions are developing to improve location flexibility, reduce costs and improve the speed of response

- Three companies have solutions moving heavy weights against gravity in different ways. All are building their first commercial or large-scale demonstrator projects.

Next week: Mechanical storage – springs and things.

- Electricity Storage – the Options

- Electricity Storage Options 3 – Springs and Tops

- Electricity Storage Options 4 – Turning up the Heat

- Electricity Storage Options 5 – Pure Electricity

- Electricity Storage Options 6 – Batteries

- Electricity Storage Options 7 – Power-to-X

- Electricity Storage Options 8 – So What Have We Learned?

Pingback:Renewable Energy and Storage – the Options – Miller Klein Associates Ltd

Pingback:Energy Storage 3 – Springs and Tops – Miller Klein Associates Ltd

Pingback:Electricity Storage Options 5 – Pure Electricity – Miller Klein Associates Ltd

Pingback:Electricity Storage 8 – So What Have We Learned? – Miller Klein Associates Ltd